In my previous post, I explained how Singapore has moved rapidly up the value chain based on international comparisons of the Manufacturing Value-Added (MVA) data. Many may look at this as less of a problem and more of a positive sign as having a higher MVA indicates progression in manufacturing activity. Critics may also argue that since we are being presented with these opportunities to upgrade, there is no reason to turn them away and should instead embrace them.

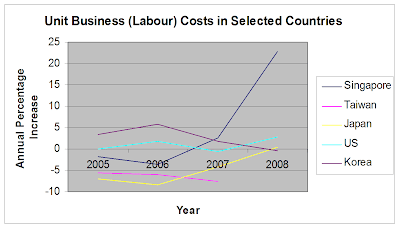

The point is that moving up the value-chain too quickly has forced business costs in Singapore to rise rapidly. This is reflected by higher unit business costs here as unit labour costs in Singapore increased by 22.8 percent in 2007 to 2008. This is enormous when compared to corresponding figures of 0.4 percent and 2.8 percent in Japan and US respectively, not to mention the drop in Korea’s unit labour costs by 0.3 percent.

Moreover, the rising labour costs in Singapore are not directly a result of higher productivity. Comparing the productivity growth rates released by the International Labour Organization, Singapore’s productivity increased by 3.7 percent from 1980 to 2002, thus showing that its productive efficiency is increasing at a slower rate than its MVA growth as well as its rising business costs. We can conclude from this that Singapore’s rapid rate of rise up the manufacturing value chain has contributed to higher unit labour costs here, and consequently higher business costs, which have not been compensated by a substantial increase in productivity. If we are to continue on this trend of moving up the value chain quickly, then we should at least ensure that productivity gets a greater push so that higher labour costs can be substantiated for our SMEs and MNCs.